LABORATORY FACILITY

The laboratory is equipped with a variety of instruments for fabrication and characterization microdevices and integrated systems. This laboratory is available mainly to MRC investigators and their students. If you are interested in using the facility, please contact Dr. Chang-Soo Kim (573-341-4529, ckim@mst.edu).

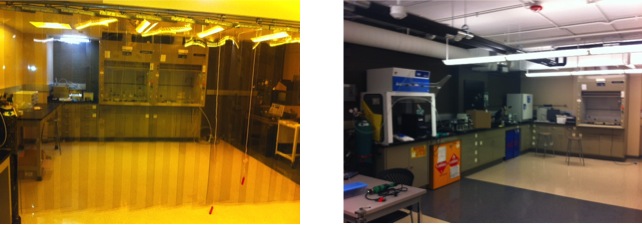

Device processing laboratory including a space with a slight positive pressure (~ 400 square-ft). A separate laboratory for characterization and instrumentation.

I. Electronic instruments

- Electrochemical workstations (Gamry FAS1 and Gamry 750): 3-electrode multi-functional (potentiostat, galvanostat, impedance) instrument.

- Multichannel electrochemical multiplexer (Gamry ECM8): 8-channel multiplexer for sequential multichannel monitoring.

- Semiconductor parameter characterization system (Keithley 4200SCS): multi-channel programmable voltage and current source-measurement-unit.

- C-V analyzer (Keithley 590): MOS capacitor analysis.

- Nanovoltmeter (Keithley 2182): dual-channel digital instrument for low level measurements of DC volts.

- Picocurrent source (Keithley 225): constant current source capable of sourcing current of 100 pA.

II. Analytical instruments

- Spectrometer (Ocean Optics USB2000-FLG): Gated CCD-based spectrofluorometer.

- Spectrometer (Tau Theta MFPF 100): Multi-frequency phase fluorometer.

- Optical power/energy meter (Newport 2935-C): Dual channel low-power optical meter.

- Ion/gas analysis system (ORION 940): analytical instrument for ion/gas monitoring and analysis (pH, electrolytes, dissolved oxygen, carbon dioxide, temperature).

- Fiber optic oxygen meter (WPI OXY-MICRO-AOT): (dissolved) oxygen monitoring system with a luminescence optical microprobe.

- Galvanic oxygen meter (WTW Inolab): (dissolved) oxygen monitoring system with a galvanic oxygen probe.

- Conductivity meter (Oakton con 100): conductivity measurement of liquid samples.

- Imaging system (Nikon DS-5M): Digital color CCD inspection system.

III. Process equipment

- Mask aligner/exposure system (Suss MA6/BA6): 4”-wafer photolithography process equipment.

- Spin coater (Laurel WB-400B-6NPP-LITE): 4”-wafer photoresist spin coating equipment.

- Reactive ion etcher (Plasma Etch PE-200): Bench top 300W dry etching system.

- Wafer bonder (Dynatex DXB-525): Wafer bonding system.

- Microprobe station (Cascade REL 100): manual microprobe station for testing of ICs in wafer or packaged platform.

- Wedge wire bonder (Kulicke & Soffa 4526): manual wedge wire bonder for interconnection.