Sponsor(s): Department of Energy (National Energy Technology Laboratory), S&T Intelligent Systems Center

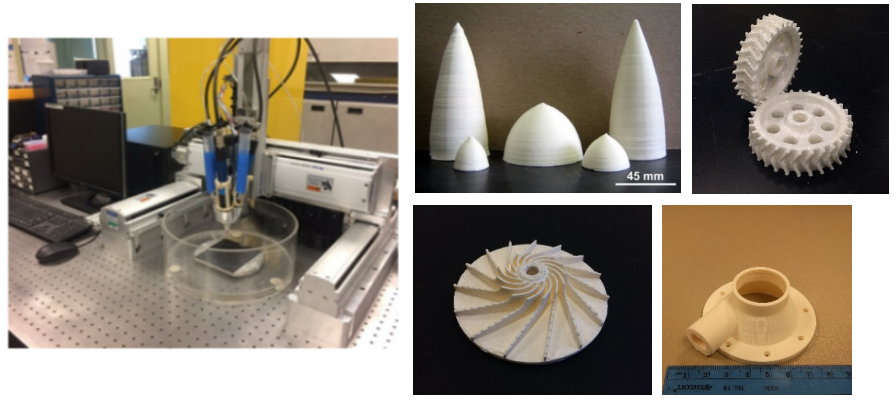

This research investigates using the ceramic on-demand extrusion (CODE) process to fabricate complex 3D parts made of ceramics and ceramic composites, with applications to aerospace, energy, and biomedical industries. CODE is a novel freeform extrusion fabrication process recently developed at Missouri S&T. This process uses layer-by-layer extrusion of aqueous pastes followed by uniform radiation drying between successive layers. The parts that we have fabricated using this process include aerospace structural components with high-temperature and ultra-high-temperature materials (e.g., alumina, zirconium diboride, and partially stabilized zirconia). This process has also been used to fabricate smart parts with embedded sensors, e.g., smart lining blocks with embedded optical fiber sensors that can used for in situ temperature and stress monitoring. Our current research focuses on fabricating composite structures made of two or more materials that can be distinct materials or graded in compositions continuously as programmed to created parts with functionally graded materials. The current research tasks include: (1) design of parts with optimal material distribution, (2) development of colloidal pastes from ceramic powder (3) simultaneous control of flow rates of multiple pastes and homogeneous mixing of pastes, and (4) evaluating the mechanical properties of fabricated parts with functionally graded materials.

Publication(s):Sponsor(s): Honeywell Federal Manufacturing & Technologies

The aim of this project is to perform fundamental research aimed at understanding the selective laser melting (SLM) process, which is an additive manufacturing technique that bonds successive layers of powder to produce metal parts with any complex 3D geometry. The main research objectives are: to characterize powder material, relate it to part properties and assess its viability for reuse/recycling; to improve part properties through optimization of process parameters; to control the microstructure of manufactured parts with sensing using an infrared camera; to tune the chemistry of input powder for the SLM process. To address these objectives, the project consists of the following tasks: (1) powder characterization, (2) material property characterization, (3) temperature effects on material properties, (4) controlling microstructure and mechanical properties, and (5) chemistry specifically for additive manufacturing.

Publication(s):Sponsor(s): Department of Energy

The objective of the project is to develop a new additive manufacturing (AM) technology, called Laser Foil Printing (LFP), for fabricating three-dimensional (3D) metal parts. Instead of using metal powders as in most existing AM technologies, the new method uses metal foils as feed stock. The procedure consists of two alternating processes: foil welding by a high-power continuous-wave laser and foil cutting by a Q-switched ultraviolet laser. The foil welding process involves two sub-processes: laser spot welding and laser raster-scan welding. The reason for using two lasers is to achieve simultaneously the high-speed and high-precision manufacturing. The results on laser foil-welding and foil-cutting show that complete and strong welding bonds can be achieved with selected parameters, and that clean and no-burr/distortion cut of foil can be obtained. Several 3D AISI 1010 steel parts fabricated by the proposed AM technology are obtained, and the micro-hardness and tensile strength of the as-fabricated parts are both significantly greater than those of the original foil. The LFP can also be used for fabricating sensor-embedded parts and for outer space manufacturing under low gravity, vacuum and low temperature environments.

Publication(s):Sponsor(s): Boeing, Stratasys, Steelville Manufacturing, S&T Center for Aerospace Manufacturing Technologies, America Makes

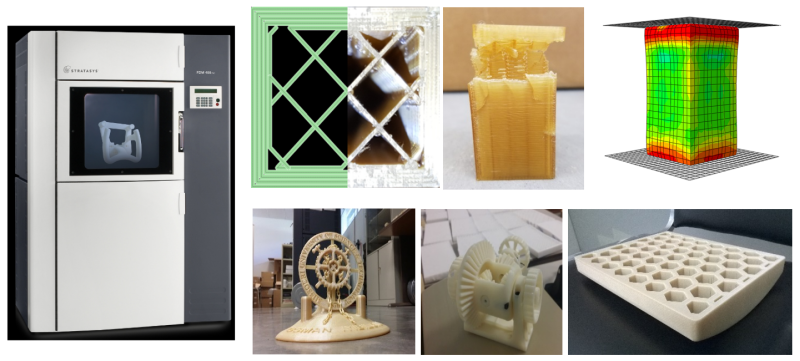

The objective of this research project is to investigate low-cost rapid tooling with Ultem (9085 & 1010) using the fused deposition modeling (FDM) process, an additive manufacturing technique that built a part layer-by-layer by extruding thermoplastic material that is supplied in the filament form. The tooling can be used in manufacturing of composites with the autoclave, vacuum assisted resin transfer molding and other processes, as well as in stamp forming applications. In this project, Ultem specimens are fabricated using the FDM process and then their mechanical properties are measured in compression, tension, and flexure tests at room and elevated temperatures. The test specimens include solid coupons and sparse-build coupons with varying build parameters including air gap, wall thickness, and cap thickness, as well as different internal lattice structures. Modeling and simulation with finite element analysis is used to predict the mechanical properties of sparse-build FDM tools and compare the predicted results with data obtained from experimental testing. The project is conducted jointly by Missouri S&T and Boeing Research & Technology.

Publication(s):Sponsor(s): Missouri Research Board, MO-SCI Corporation, S&T Intelligent Systems Center, Keith and Pat Bailey Professorship Fund

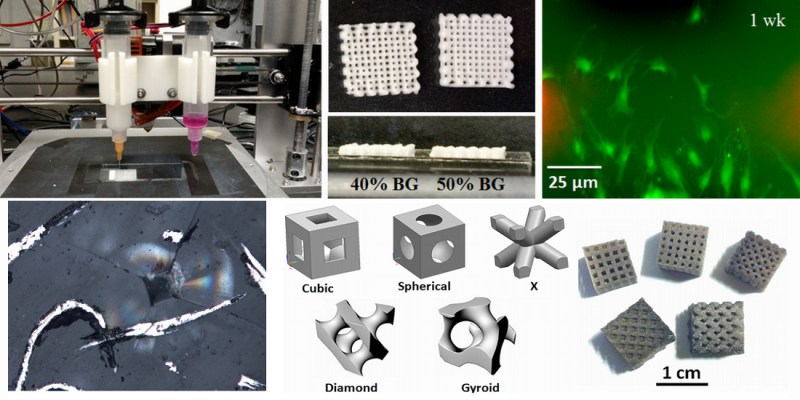

In this research, we first investigated the fabrication of scaffolds with engineered porosity from 13-93 bioactive glass using the selective laser sintering (SLS) process and an extrusion-based process. The SLS process is a powder-bed based additive manufacturing technique that fabricates a scaffold layer-by-layer by controlling laser scans to sinter the mixture of ceramic and binder particles in a powder bed. Pore geometry in the scaffold is shown to play a crucial role as it affects not only the mechanical properties and degradation over time as well as the amount of bone regeneration upon implantation. In the extrusion-based process, aqueous-based bioactive glass paste was deposited layer-by-layer using a micro-sized nozzle. The fabricated green scaffolds are then heat treated to remove the binder. Our sintered scaffolds demonstrated an average compressive strength of 136 MPa, which is the highest reported in additive manufacturing of bioactive glass. To improve the toughness of the scaffold, titanium fibers were added to the paste to increase the fracture toughness and flexure strength of the scaffold. Because a major limitation of synthetic bone repair is insufficient vascularization in the interior of the porous implant, our current research focuses on 3D bioprinting of mesenchymal stem cells (MSCs) suspended in the hydrogel and polymer-bioactive glass composite. Bioprinting a scaffold with these materials would offer a 3D environment for complex and dynamic interactions that govern the MSCs behavior in vivo. Bioactive glass is added to a mixture of polymer and an organic solvent to make an extrudable paste. Porous polymer-glass composite scaffolds are fabricated by extruding this paste using a syringe, and MSCs suspended in the hydrogel is deposited using another syringe. In vitro assessment indicates the viability of the process to print MSCs suspended in Matrigel. Fluorescence images from the live-dead assay indicate that cells are alive and actively moving in the scaffold.

Publication(s):Sponsor(s): National Science Foundation

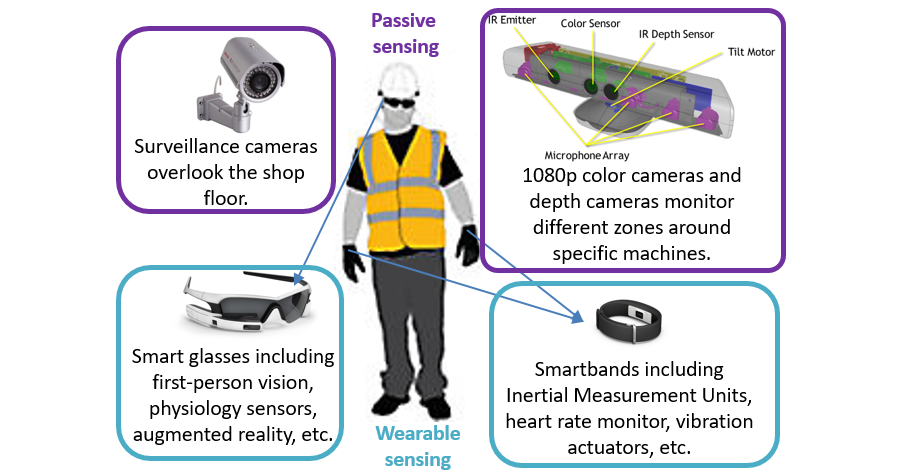

Smart manufacturing integrates information, technology, and human ingenuity to inspire the next revolution in the manufacturing industry. Manufacturing has been identified as a key strategic investment area by the U.S. government, private sector, and university leaders to spur innovation and keep America competitive. However, the lack of new methodologies and tools is challenging continuous innovation in the smart manufacturing industry. This award supports fundamental research to develop a cyber-physical sensing, modeling, and control infrastructure, coupled with augmented reality, to significantly improve the efficiency of future workforce training, performance of operations management, safety and comfort of workers for smart manufacturing. Results from this research are expected to transform the practice of worker-machine-task coordination and provide a powerful tool for operations management. This research involves several disciplines including sensing, data analytics, modeling, control, augmented reality, and workforce training and will provide unique interdisciplinary training opportunities for students and future manufacturing engineers.

Publication(s):Sponsor(s): National Science Foundation

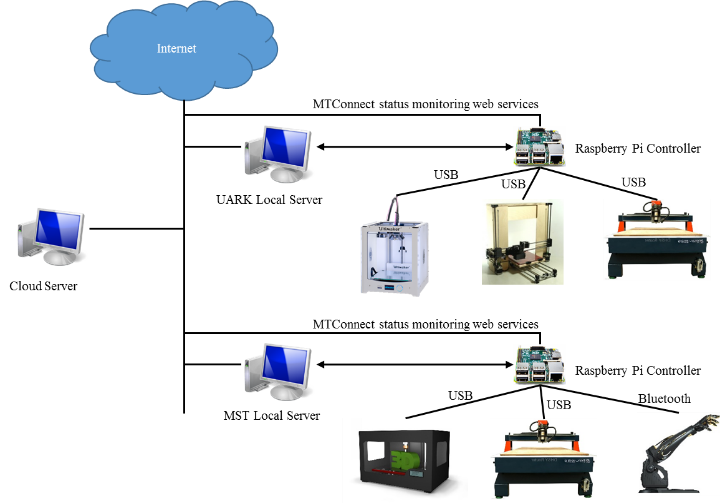

This is a collaborative research project between Missouri S&T and the University of Arkansas. This project is dedicated to the development of a framework including architecture and protocols for communication among various manufacturing resources and management of manufacturing services for cyber-physical systems in cloud manufacturing. The practical aim is of the cyber-physical system to increase the productivity and efficiency of industrial enterprises by managing and sharing geographically dispersed manufacturing resources and connecting customers with manufacturing companies. The research consists of the following tasks: (1) scalable service-oriented architecture for scalable cyber-physical manufacturing, (2) network architecture and plug-and-play protocols, (3) methods for virtualization of manufacturing resources (e.g., CNC machines, 3D printers, CMMs), and (4) development of a testbed to evaluate the developed architecture, protocols, and methods.

Publication(s):Sponsor(s): National Science Foundation

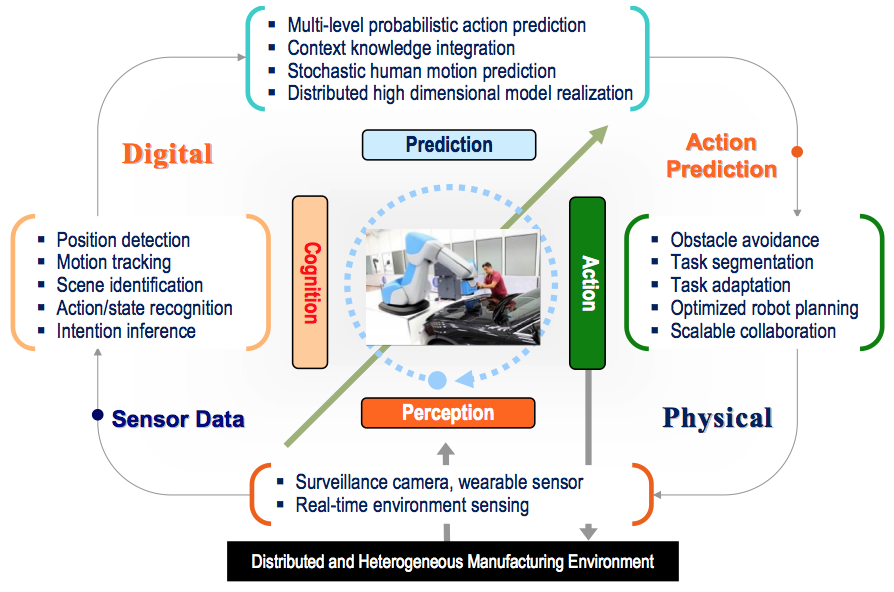

A strong manufacturing industry is fundamental to a nation's economic prosperity. Collaborative human-robot workplaces, which combine human's flexibilities and robot's productivities, are critical to high productivity for many industrial companies. While robots have been rapidly transforming the manufacturing industry, effective, efficient and safe coordination between humans and robots on the factory floor remains a major challenge, with a set of critical issues to be addressed in the areas of sensing, cognition, prediction and control. The research objective of this project is to design, develop, and systematically evaluate in a realistic manufacturing setting an intelligent human-robot collaboration system enabled by ubiquitous sensing, customized cognition, real-time prediction, and intelligent control methods, which ensure operation safety and production efficiency, for deployment on the factory floor. Specific research tasks include: 1) a suite of multi-modal sensors will be designed and integrated to sense human operators, robots, machines, parts and tools in the smart factory; 2) machine learning based cognition algorithms will be explored to annotate the big data generated by monitoring multiple humans and robots in the manufacturing cell; 3) variable-order Markov models and distributed particle filters will be investigated to accurately parse human actions and environmental contexts for efficient future action prediction; 4) multilayer control structures subject to multi-scenario human-robot interaction response levels will be developed to adapt tasks in real time for controlled robot motions, and to optimize the human-robot collaboration; and 5) the fundamental research results will be implemented and evaluated in an intelligent human-robot collaboration testbed.