U.S. Product Standard PS 1—Construction of Industrial Plywood

all-veneer panels/plywood

1. prescriptive specification - how to make plywood

2. performance standard - load capacity, dimensional stability, moisture

Performance Rated Panels - APA

- 1/2" → 15/32"

- 5/8" → 19/32"

- 3/4" → 23/32"

Sanded Panels

reduced thickness

different cross-sectional properties in strength calculations

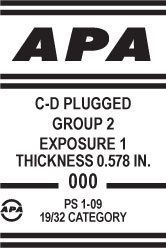

grade stamp

- veneer grade of face and back

- minimum species group of face and back

- exposure durability classification

- product standard

- mill number

- qualified inspection and testing agency

sourceGrades and Specifications - APA

Sheathing Grades

roof, floor, wall

C-C (exterior)

C-D (exposure 1)C-C STR I

C-D STR I

grade stamp

- veneer grade of face and back

- minimum species group of face and back

- exposure durability classification

- product standard

- mill number

- qualified inspection and testing agency

- thickness

- span rating

source

Span Rating

1. max. recommended span as roof sheathing

2. max. recommended span as subflooring

no need for structural calculations

assumptions

- continuous over two or more spans

- strong direction

- edge support requirements

ASD/LRFD Manual table M9.1-1

IBC table 2304.7(3)

Thickness

different thicknesses for same span

Panel Design Specification - APA table 5

usually minimum thickness is available

sheathing loads - minimum span rating

diaphragm loads - minimum panel thickness