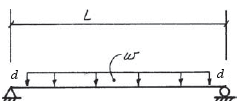

Given

closely spaced floor beams

Load D = 18 psf

L = 50 psfLoad combination D+L (ASD)

1.2D+1.6L (LRFD)Span L = 14 ft Member spacing Tributary width = b = 16 in. OC

wD = 18 lb/ft2 (1 ft/12 in.)2 x 16 in. = 2 lb/in.

wL = 50 psf (1 ft/12 in.)2 x 16 in. = 5.556 lb/in.Stress grade and species No. 1 Hem-Fir Unbraced length lu = 0 Moisture content MC ≤ 19% Live load deflection limit Allow. ΔL ≤ L/360 = 0.4667 in.

Allow. ΔD+L ≤ L/240 = 0.7000 in.Dry-service conditions Normal temperatures Bending about strong axis

Trial Size

Fb = 975 psi (NDS Supplement table 4A)

vertical ground reactions: wL/2

Vmax = +/- wL/2

Mmax = wL2/8S ≥ Mmax/Fb = (7.556 lb/in.) x (14 ft x 12 in./ft)2 / (8 x 975 lb/in.2) = 27.34 in.3

S2x10 = 21.39 in.3 ✘ (NDS Supplement table 1B)

S2x12 = 31.64 in.3 ✓ (NDS Supplement table 1B)

Size Category (NDS Supplement tables 1A and 1B)

dimension lumber

dressed size: 1.5" x 11.25"

A = 16.88 in.2

Sxx = 31.64 in.3

Ixx = 178.0 in.4

Reference Design Values (NDS Supplement table 4A)

Fb = 975 psi

Fv = 150 psi

E = 1,500,000 psi

Adjusted ASD Values: F'b, F'v , E'

NDS Supplement table 4A Cr = 1.15

CM = 1

Cfu = 1

CF = 1NDS Supplement section 2.3

CD = 1 (L)

Ct = 1NDS Supplement section 3.3 CL = 1 (lu = 0)

NDS Supplement section 3.7

CP = 1 (not a column)

NDS Supplement section 3.10

Cb = 1 (not enough info given)

NDS Supplement section 4.3 Ci = 1

NDS Supplement section 4.4

CT = 1 (not a truss)

Property Reference Design

Values (psi)

(Table 4A)Adjustment Factors (Table 4.3.1) Adjusted Design

Values (psi)CD CM Ct CL CF Cfu Cr CP Ci CT Cb bending stress Fb 975 1 1 1 1 1 1 1.15 1 1,121 tension stress parallel to grain Ft 625 1 1 1 1 1 -- shear stress parallel to grain Fv 150 1 1 1 1 150 compression stress perpendicular to grain Fc⊥ 405 1 1 1 1 -- compression stress parallel to grain Fc 1,350 1 1 1 1 1 1 -- modulus of elasticity (or MOE) E 1,500,000 1 1 1 1,500,000 modulus of elasticity for stability calculations Emin 550,000 1 1 1 1 --

Actual Stresses (ASD) and Deflection

vertical ground reactions: wL/2

Vmax = +/- wL/2

Mmax = wL2/8fb = M/S = (7.556 lb/in.) x (14 ft x 12 in./ft)2 / (8 x 31.64 in.3) = 842.5 psi

fv = 1.5V/A = 1.5 (7.556 lb/in. x 14 ft x 12 in./ft) / (2 x 16.88 in.2) = 56.40 psi

Reduced Shear (NDS section 3.4.3)

fv reduced = 1.5 (7.556 lb/in. x (14 ft x 12 in./ft - 2 x 11.25 in.)) / (2 x 16.88 in.2) = 48.85 psiSee formula 11 for the deflection.

ΔL = 5(5.556 lb/in.)(14 ft x 12 in./ft)4 / 384(1,500,000 psi)(178.0 in.4) = 0.2158 in.

ΔD+L = 5(2/2+5.556 lb/ft)(14 ft x 12 in./ft)4 / 384(1,500,000 psi)(178.0 in.4) = 0.2547 in. (dead load may be reduce by 1/2 if MC < 16% when installed and kept dry, IBC table 1604.3 footnote d)

ΔD+L = 5(2+5.556 lb/ft)(14 ft x 12 in./ft)4 / 384(1,500,000 psi)(178.0 in.4) = 0.2935 in. (if 16% < MC < 19%)

Is Member Adequate? (ASD)

bending: 1,121 psi > 842.5 psi ✓

shear: 150 psi > 56.40 psi ✓ (ok, so no need to consider reduced shear)

deflectionL: 0.4667 in. > 0.2158 in. ✓

deflectionD+L: 0.7000 in. > 0.2547 or 0.2935 in. ✓

Notches

NDS section 3.2.3, NDS section 4.4.3

At the ends, notches cannot exceed 1/4 of the depth.

11.25 in. / 4 = 2.813 in. > 1 in. ✓

In the outer thirds, notches cannot exceed 1/6 of the depth.

In the middle third, notches cannot exist.

NDS section 3.4.3

Vmax = wL/2 = 7.556 lb/in. x 14 ft x 12 in./ft / 2 = 634.7 lb

V 'r = (2F'vbdn/3)(dn/d)2 = (2 x 150 psi x 1.5 in. x (11.25 -1 in.)/3) ((11.25-1 in.)/11.25 in.)2 = 1276 lb

1276 lb > 634.7 lb ✓

|

Nominal LRFD Values

Adjusted LRFD Values

Adjusted LRFD Moment and Shear Resistances

Factored Moment and Shear (LRFD) and Actual Deflection

Is Member Adequate? (LRFD) |