Experimental

Procedures

- Be sure to write down all of the dimension measurements

for the beam you are using. In the sample results, the stainless steel

half was on the top and the aluminum half was on the

bottom. This may be reversed if you desire.

- Set up the strain indicators just as in previous experiments (quarter-bridge circuit).

This time we will

use two axial strain gages, one on the top surface and

one on the bottom surface of the beam. The gage factors

may not be the same for both strain gages.

- The axial strain on the top surface will decrease with

increasing load because the top of the beam is in pure

compression, and the axial strain on the bottom surface

will increase with increasing load because the bottom of

the beam is in pure tension.

If using dead weights

- Place the weight hanger on the beam (making sure it does not touch the

lathe bed), and zero the strain indicators.

- Take strain measurements for 10 loads in 10 lb increments up to 100 lb.

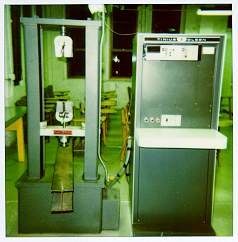

If using the TO universal testing machine

- Place a piece of bar stock between the beam and

the load head.

- Zero the strain indicators and the load readout

while the load head is not in contact with the

bar stock.

- Set the load range to 600 lb.

- Always keep the load-head speed on slow.

- Press the "Lower" button to lower the

load head and apply the load. You can raise the

load head to decrease the load if needed.

- The load knob has a dead spot, so it is hard to

stop the load on even increments.

- Take strain measurements for 10 loads in

approximately 10 lb increments up to 100 lb.