|

|

10 kg minor load

100 kg major load

1/16" diameter, hardened steel indenter

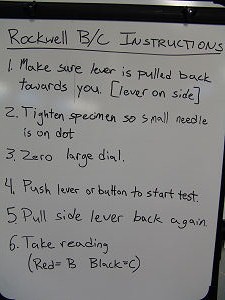

Procedures

- Pull back handle to set the major load.

- Position the specimen and tighten it up until the small needle is on the dot. This applies the minor load.

- Align the "set" mark with the large indicator needle.

- Push the button or lever.

- After motion of indicator needle has stopped for 3 to 5 seconds, pull back handle carefully to release the major load.

- Read the Rockwell B hardness number using the red scale, or read the Rockwell C hardness number using the black scale.

- Repeat until three Rockwell measurements have been made and then average the results. (Additional tests may be performed if values are not in reasonably close agreement.)

- Estimate the tensile strength from the average Rockwell hardness number using the conversion chart on the wall.