From The Testing and Inspection of Engineering Materials,

3rd Ed., by H.E. Davis, G.E. Troxell, and C.T. Wiskocil, McGraw-Hill, 1964, p. 163.

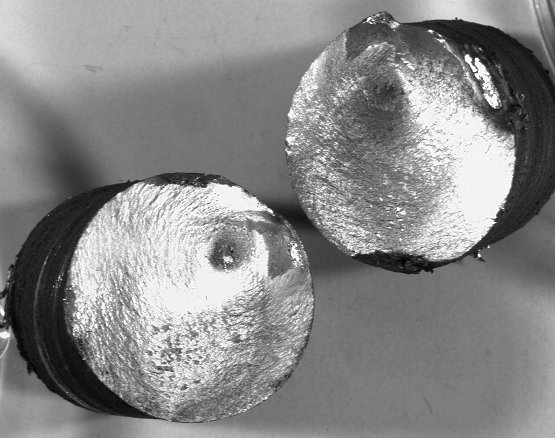

Mild vs High-Strength Steel

Photos by Jeff Thomas, November 1997

Acrylic

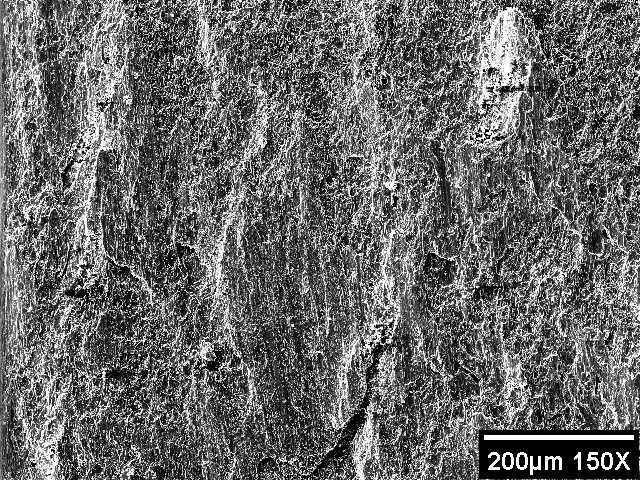

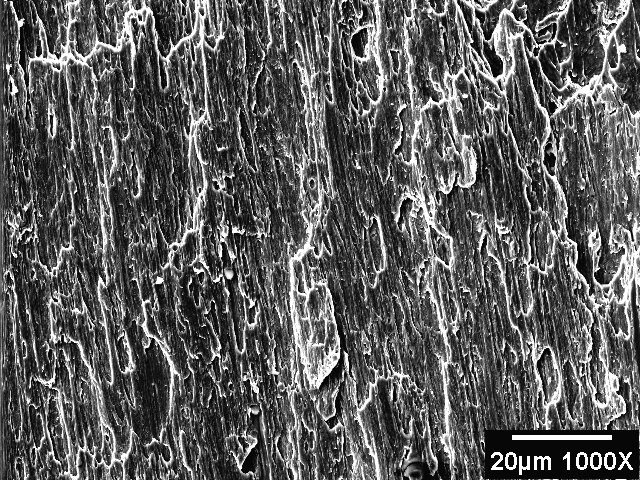

A36 Steel

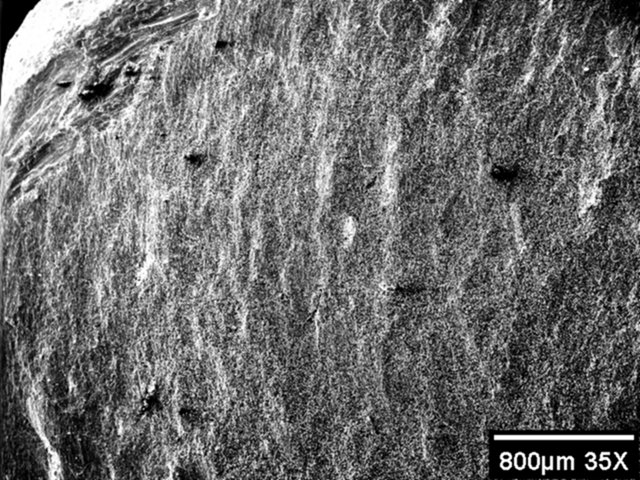

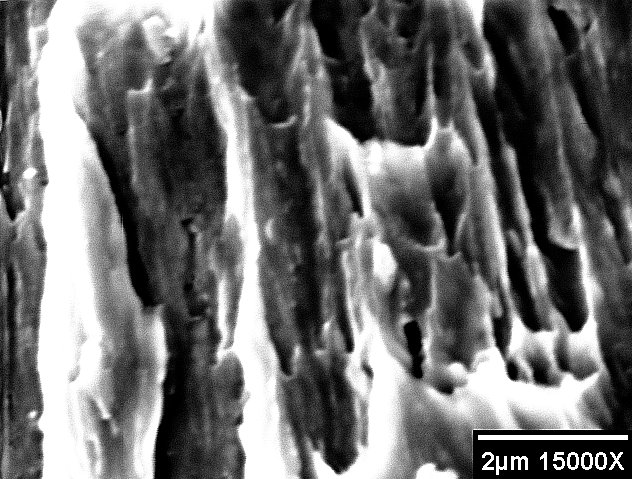

Note that the microvoids have been elongated in the direction of shear.

Taken by Jeff Thomas, November 1997, with a JEOL SEM

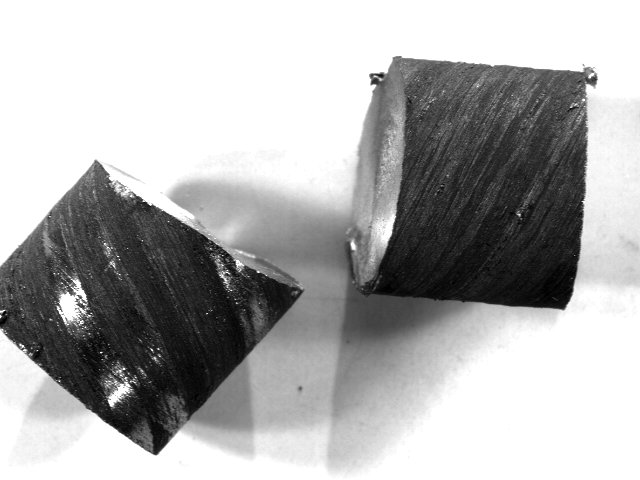

Chalk

"Chalk is a brittle material, and it fails according to the maximum normal stress theory. That is, under combined stress states failure will occur when the maximum tensile stress equals the ultimate strength in a simple tension test. Furthermore, the fracture, which displays no evidence of plastic flow, always occurs on a plane perpendicular to the maximum tensile stress. This goniometric character of the fracture surface offers a useful vehicle for demonstrating qualitatively that stress states do in fact combine in the manner predicted by elementary mechanics of materials.

After a little practice with the chalk you will be able to control the relative axial and torsional loads to vary the fracture direction over a considerable angle."

From The VRE Technical Education Newsletter, No. 10, January 1975, Vishay Research and Education, p. 3.