There are grades below #2 Common, but they're typically not suitable for woodworking

Grades of Softwoods

Softwoods are divided into dimensional lumber, with a grade based on strength, and appearance boards, which are typically used for woodworking projects. Grading of softwoods is overseen by a number of different agencies, so you will be more likely to find some variations in terminology. Grades listed here are from highest to lowest.

Grade What It Means C Select Almost completely clear of defects. Widely used for interior trim and cabinets. D Select Fine appearance, similar to C Select. May have dime-sized knots. 1 Common Best material for high quality pine with a knotty look. Knots will be tight, meaning they won't fall out, and generally small. 2 Common Tight knots, but larger than found in 1 Common. Often used for paneling and shelving. Very suitable for general woodworking projects.

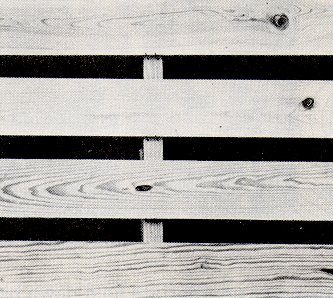

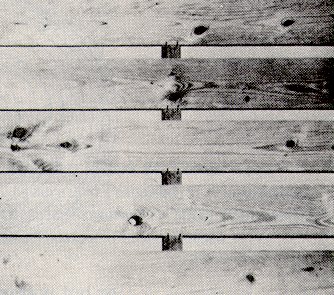

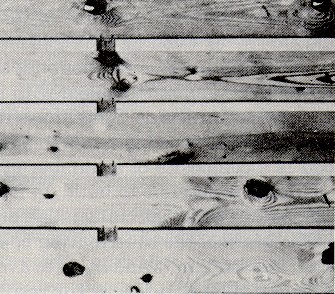

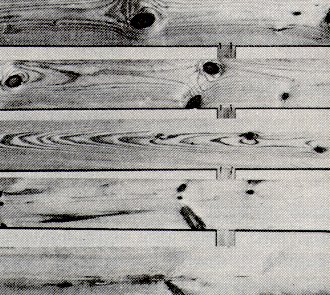

Grade 1 Pine Grade 2 Pine Grade 3 Pine Grade 4 Pine

Common Lumber Defects

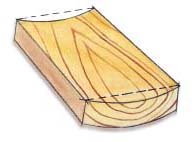

BOW - Warp on the face of a board from

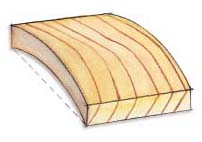

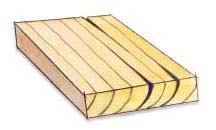

end to end.CUP - Hollow across the face of a board. CROOK - Warp along the edge line; also

known as crown.

KNOT or KNOTHOLE - A tight knot is

usually not a problem; a loose or dead knot,

surrounded by a dark ring, may fall out or

may have already left a hole.

SPLIT - Crack going all the way through

the piece of wood, commonly at the ends.

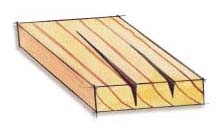

TWIST - Multiple bends in a board.

CHECK - Crack along the wood's annual

growth rings, not passing through the

entire thickness of the wood.

SHAKE - Separation of grain between the

growth rings, often extending along the

board's face, and sometimes below its

surface.

WANE - Missing wood or untrimmed bark

along the edge or corner of the piece.

Lumber Grading Stamp

When lumber of the same species and size is still at the mill, it is designated and separated by grade. It is then identified by a stamp and often inventoried by its grade and species. Different lumberyards sometimes use different names for the same grade. Grade designations depend on particular defects such as knots or wane. Grade does not indicate consistency of color or grain patterns.

Manufacturer: Mill's number, name, or symbol. (ex. 12)

Certification mark: Symbol of agency providing quality-control supervision. (ex. WWP®)

Grade: Often abbreviated. 1 Common shown. (ex. 1COM)

Moisture content (MC:) Abbreviation for MC when board surfaced. MC 15 is 15% or less;

KD or S-DRY is 19% or less; S-GRN is green wood with more than 19% MC. (ex. S-DRY)Species mark: Symbol or abbreviation for types of tree. Example shown is Ponderosa pine. (ex. PP)