|

This week you will test the hardness of polymers and metals. The hardness of wood and fasteners will be determined at other times in the semester. Hardness does not directly relate to an IDE 110 topic, but it has the most complex stress state of our testing techniques. Therefore it somewhat ties with combined loading. You will run one metal-Brinell, one metal-Rockwell, and one polymer-Durometer or -Rockwell test. You will then compare these hardness and estimated tensile strength values to references values. We have copper, brass, three types of aluminum, five types of steel, iron, LDPE, HDPE, polypropylene, two types of PVC, and acrylic for you to choose from. We have both rectangular and cylindrical samples for several of the metals. You will have to select the appropriate hardness scale (e.g. Rockwell B or Rockwell C) and correct for readings on cylindrical surfaces. |

|

|

Video Lecture (30 minutes) Hardness Testing Notes

|

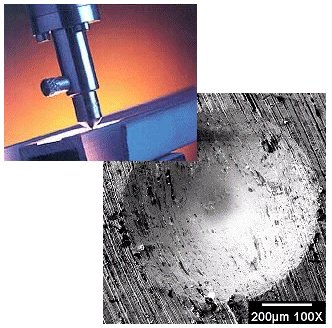

SEM image by Jeff Thomas, 1997 |

1. DrD

Polymer Consulting Services

2. Dr. Shakhashiri, University of Wisconsin-Madison